Do you have any questions or are you ready to dig deeper into your projects with one of our experts? We are here for you.

Don't have an account?

Sign upOr log in with

Navy vessels have traditionally been made using steel, but there is an increasing interest in composite materials which not only decrease the weight of the ship but also make it difficult for others to spot it due to the low radar transmission properties of our materials.

All structural components, hulls, decks, bulkheads, floors and masts, as well as transoms, engine beds and winch bases, can be made lighter, stronger and stiffer with our solutions.

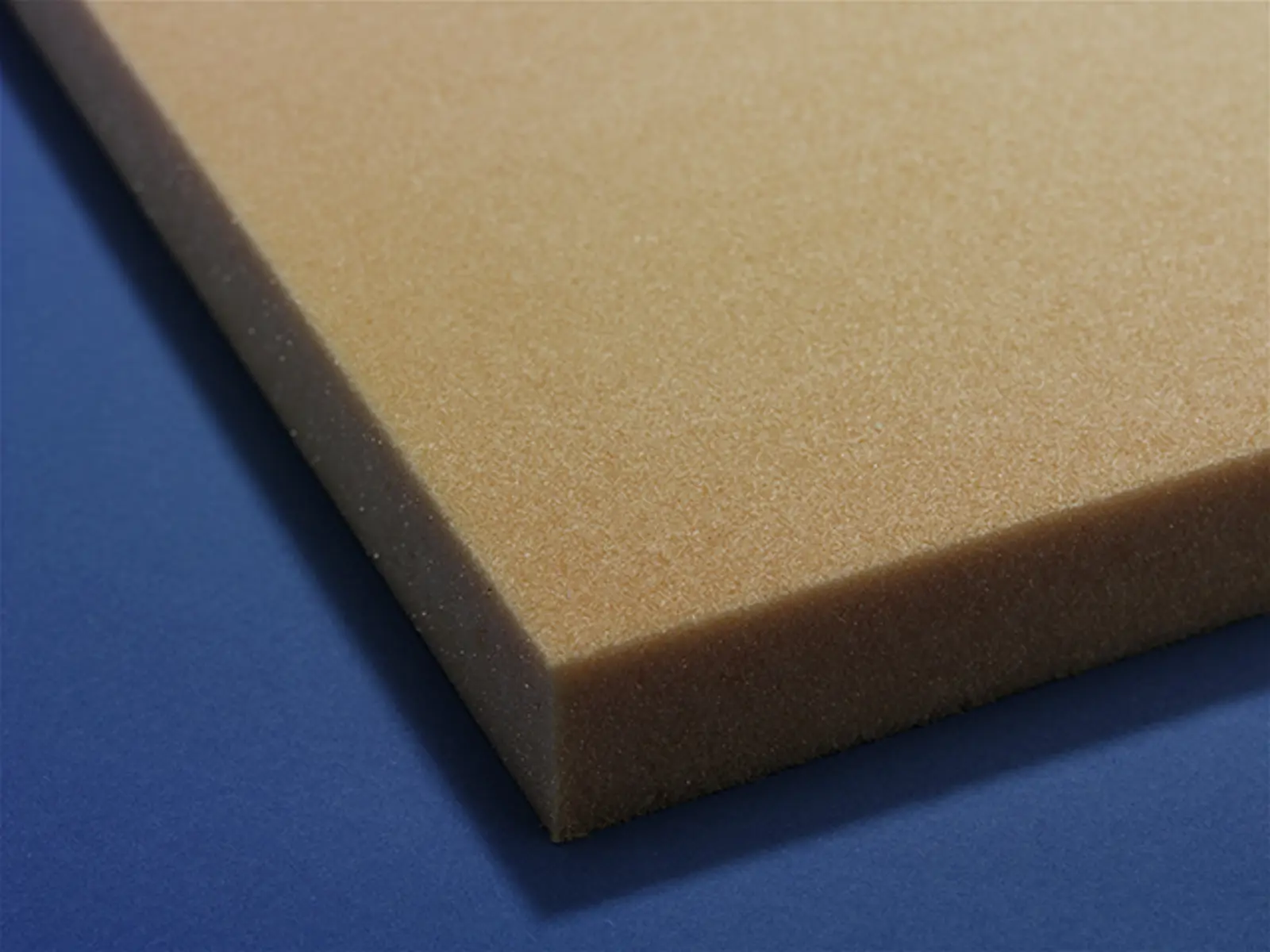

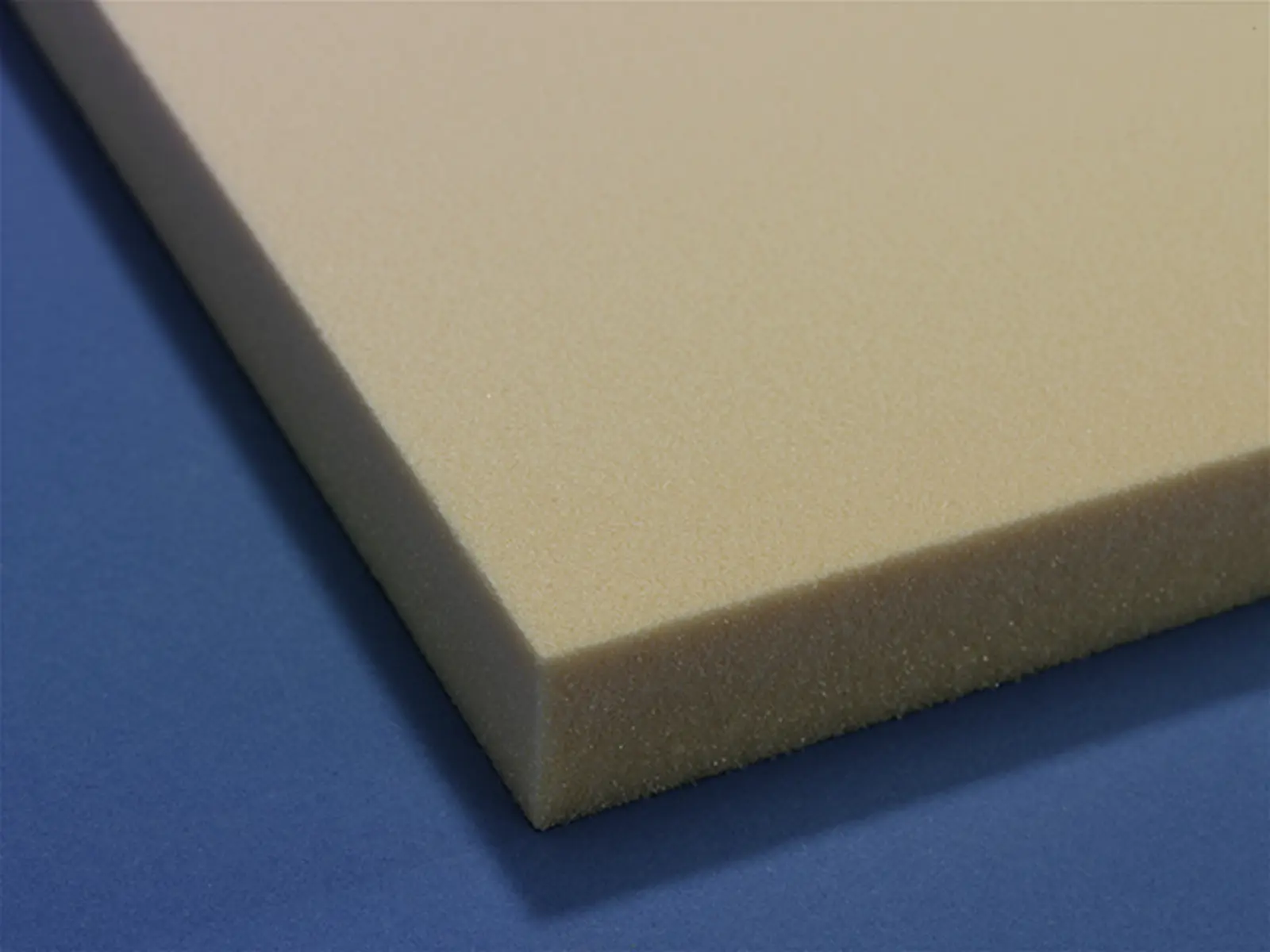

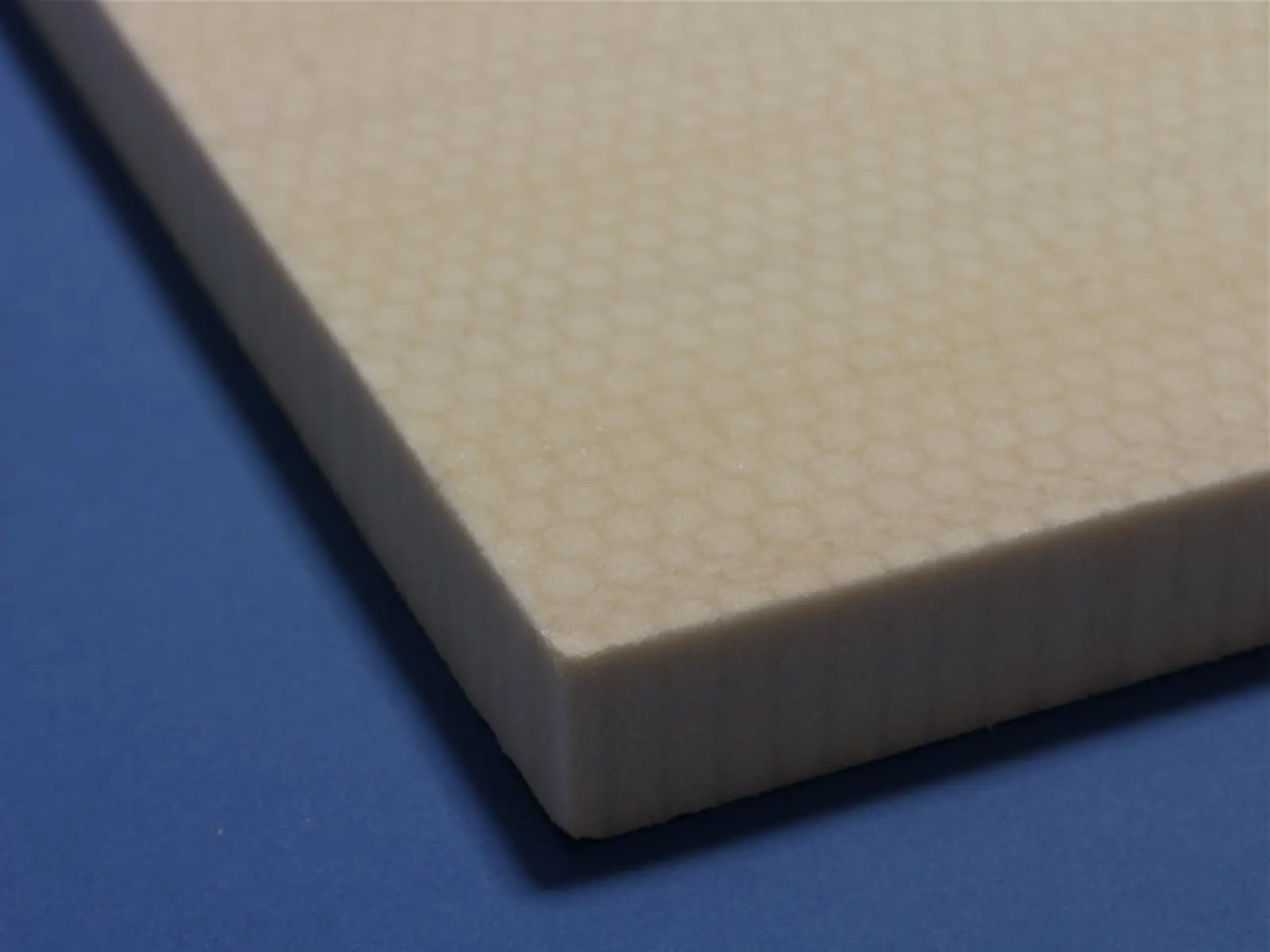

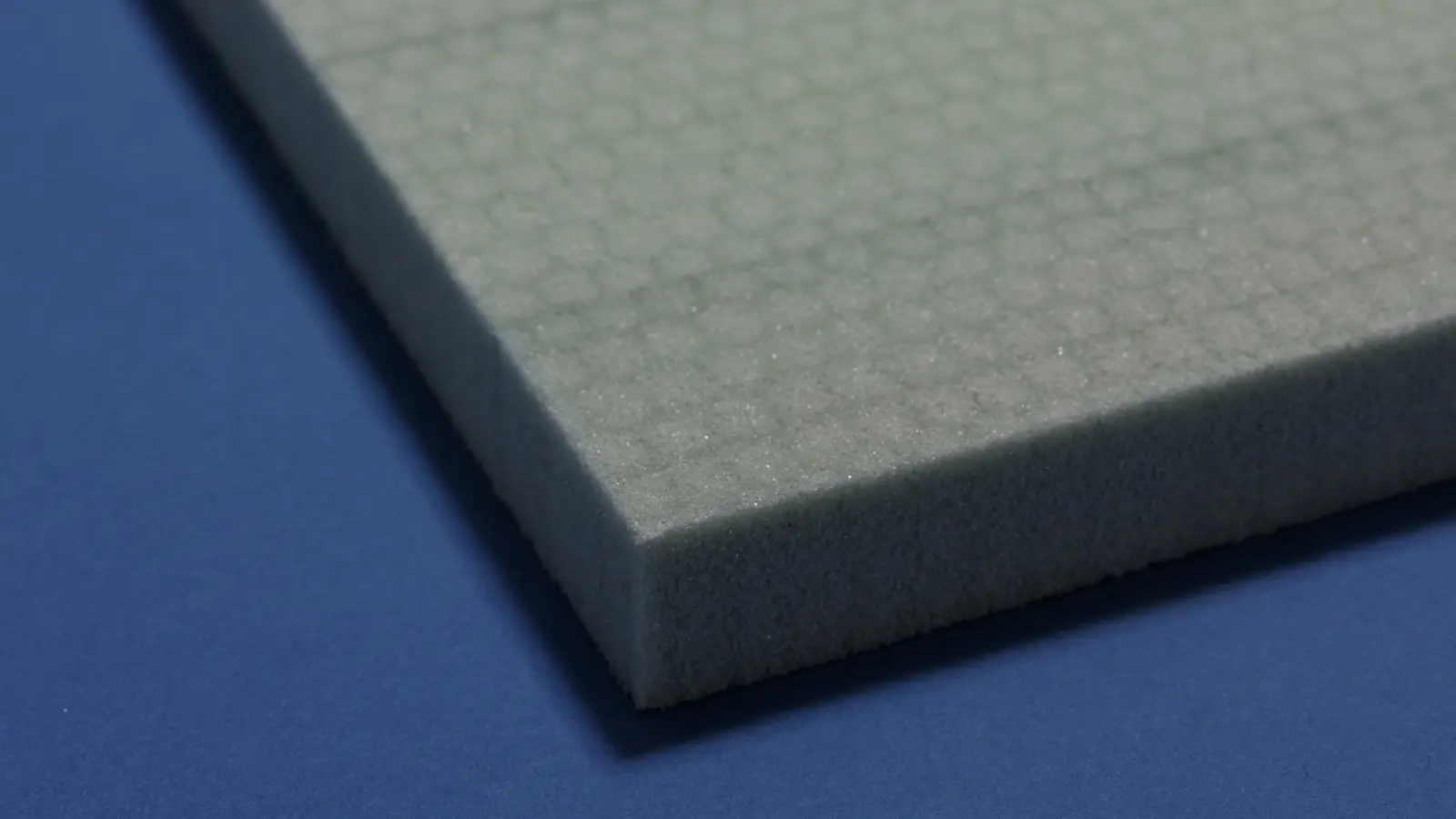

Our core materials include many benefits, such as good service life and low resin uptake. They provide excellent fatigue and slamming properties in sandwich structures, which makes them particularly ideal for patrol boats, coast guard vessels and other special crafts that often operate in high-sea conditions and at high speed. The closed cells significantly reduce water uptake and offers good chemical resistance,

The products from Diab are easily formable and have great machinability, which, in combination with a wide range of finishes, offer a design freedom and surface treatment that is far superior to traditional materials. In addition, our kitting options make manufacturing easier and more accurate. The result is a durable vessel with long service life, reduced fuel consumption and low flammability. Materials are DNV- and LR-certified.

Find and download certificates, datasheets and other documents here.

DownloadFind the tools and services you need to draw all the benefits from our materials.

See our tools

To ensure that we give you the best experience on our website. Find out more about the cookies we use in our cookie policy.

Required

These cookies are required in order for the website to function normally.

Statistics

These cookies are used to collect statistical information.

Marketing

These cookies are used for marketing-related purposes.