Flow

Finishing options to best utilize a plain sheet.

Read moreDo you have any questions or are you ready to dig deeper into your projects with one of our experts? We are here for you.

Don't have an account?

Sign upOr log in with

A combination of our Flow and Form finishing options is optimal when the core needs to not only adapt to the curvature of your product, but also distribute resin in your manufacturing process. Diab has developed unique solutions especially suited to the needs of fast and secure vacuum-assisted manufacturing, so you can get the best performance out of every design.

Flow

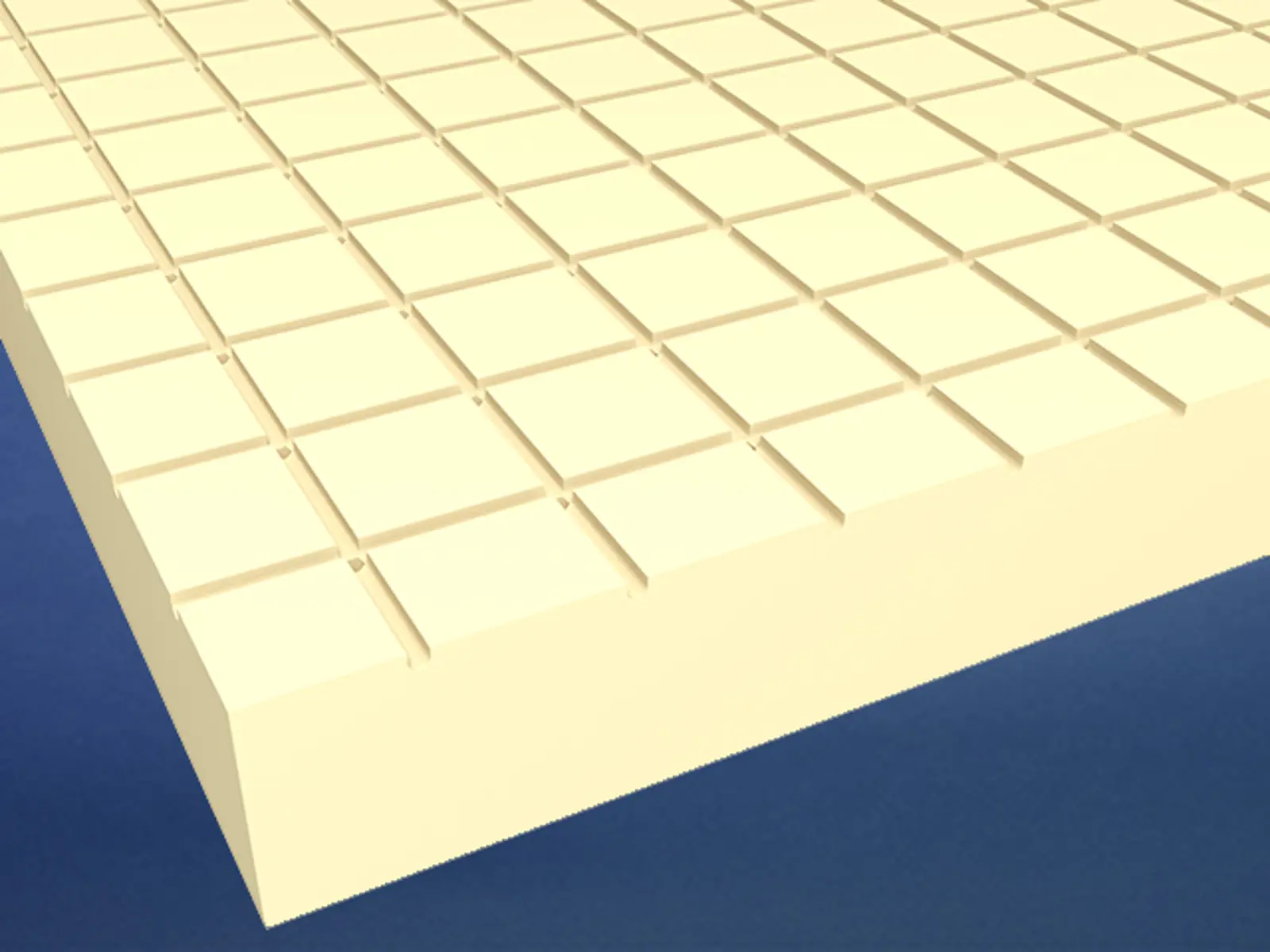

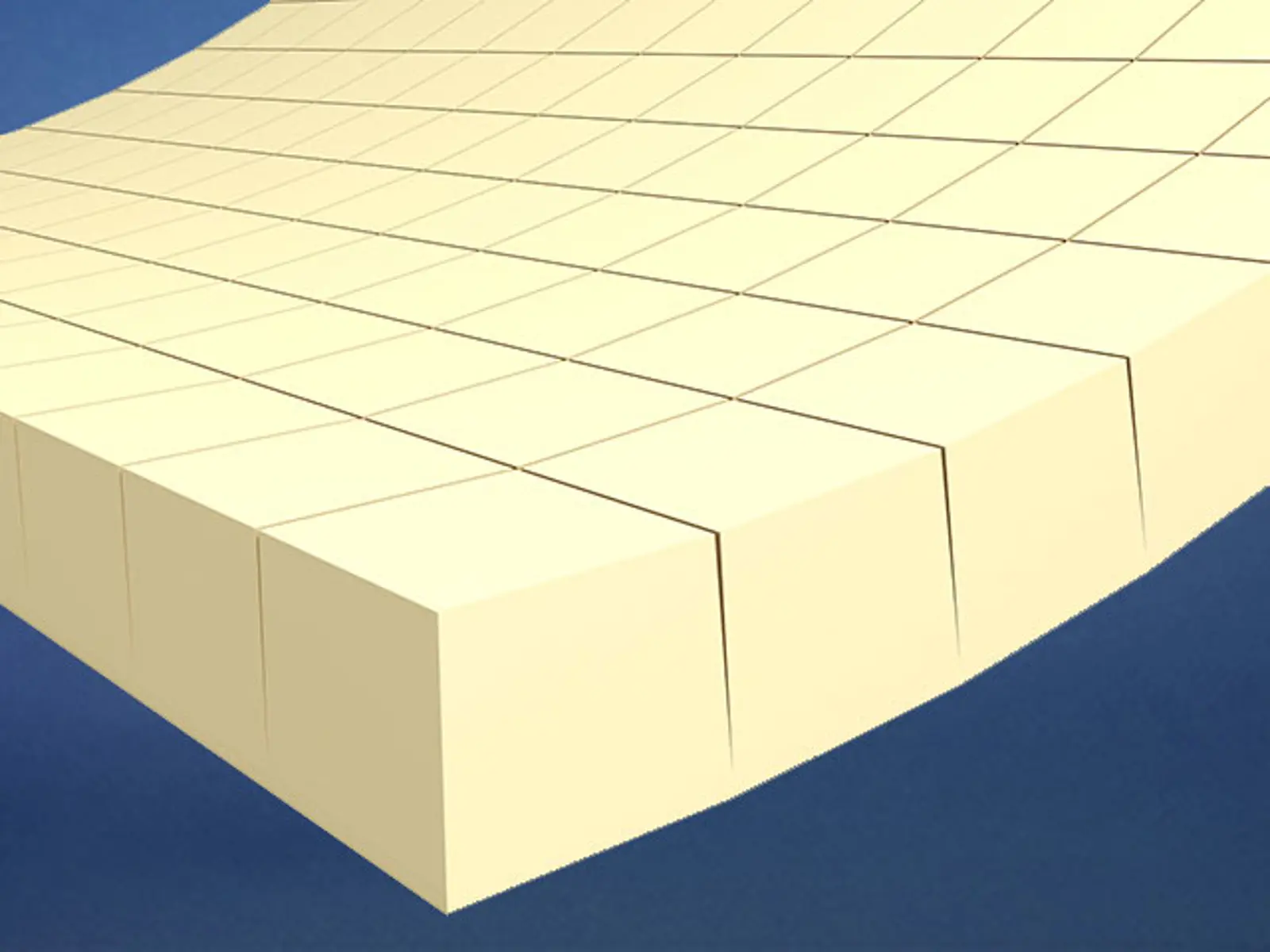

To distribute resin, there are several options. Grooves and grid-scoring will distribute resin, while perforations will prevent air from being trapped under the core, ensuring good wet-out and bonding to the laminate. Grooved and perforated combinations remove the need for an additional distribution medium within the laminate or above it.

Form

To create curves, you have formable finishing options. Grid-scored finish makes the core conform easily to the mould for complex shapes. One-direction cut finish is similar to a grid-scored finish, but with cuts in one direction only. Double-cut finish allows curvature into panels without applying a scrim.

Selecting the right finishing will impact not only the weight of the final component and surface quality, but can also speed up manufacturing time.

Diab will help you select the most efficient flow finishing based on your specific requirements.

Datasheets for all finishing options are available under Brochures, Datasheets & Certificates.

Find and download certificates, datasheets and other documents here.

DownloadFind the tools and services you need to draw all the benefits from our materials.

See our tools

To ensure that we give you the best experience on our website. Find out more about the cookies we use in our cookie policy.

Required

These cookies are required in order for the website to function normally.

Statistics

These cookies are used to collect statistical information.

Marketing

These cookies are used for marketing-related purposes.