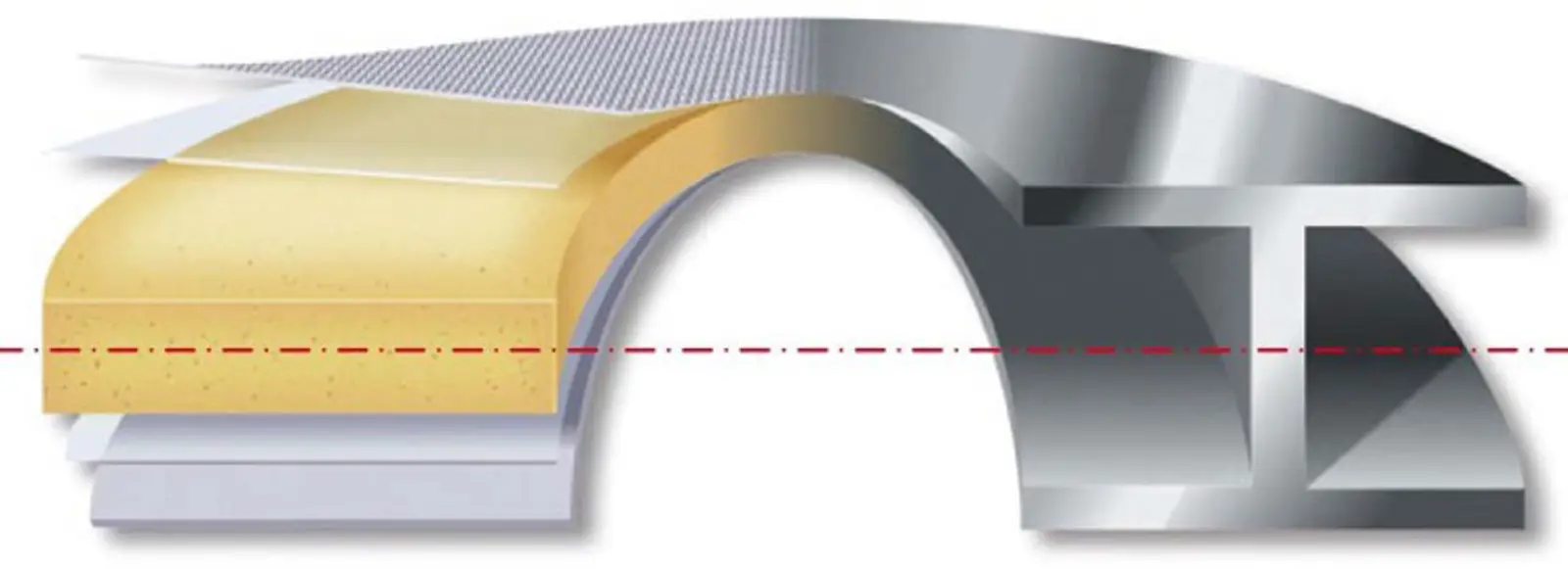

Structural core materials

Light, strong and easy to shape, a sandwich core composite has many advantages for almost any application.

Learn moreComposite materials are made from two or more constituent materials with significantly different physical or chemical properties, that when combined, form an overall structure with characteristics different from the individual components.

The basic idea is simple; the execution is a bit more advanced. Two thin, strong and stiff skins, of fiber reinforced plastics or solid material, are attached to a lightweight core by press-bonding or lamination. The result is a component with a very high stiffness-to-weight and high bending strength-to-weight ratio. A variety of core materials is used to give the final product additional desired features, such as FST resistance or insulation.

Find out more in our Guideline for Core and Sandwich - Download pdf

Light, strong and easy to shape, a sandwich core composite has many advantages for almost any application.

Learn moreGaining ground in almost every market, potential applications for these lightweight yet strong foam core materials are limitless.

Learn moreWith different manufacturing methods we can help you make the most of your composite core solution.

Learn moreSustainability is one of our top business priorities and we strive to further improve our performance.

Learn more