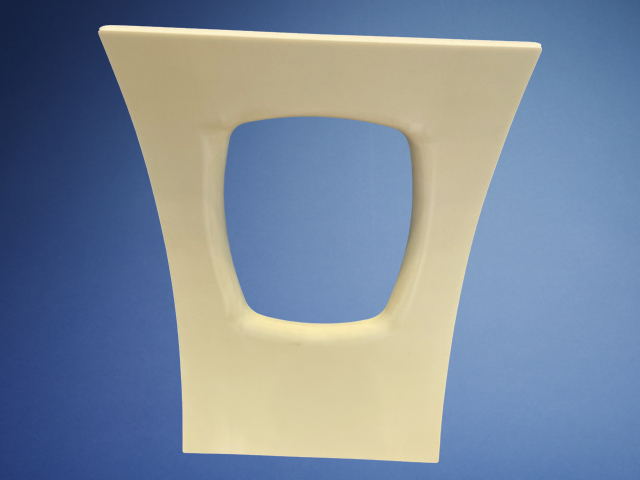

At AIX, you can also examine Diab’s award-winning 100% thermoplastic, recyclable sidewall panel for aircraft interiors. In 2022, it won three awards: the JEC Innovation Award, the Crystal Cabin Award, and the CAMX ACE, and is finalist for the Trinity Award in June 2024. In a successful collaboration with Hutchinson, the concept demonstrates technology compliance with typical aerospace customers’ expectations.

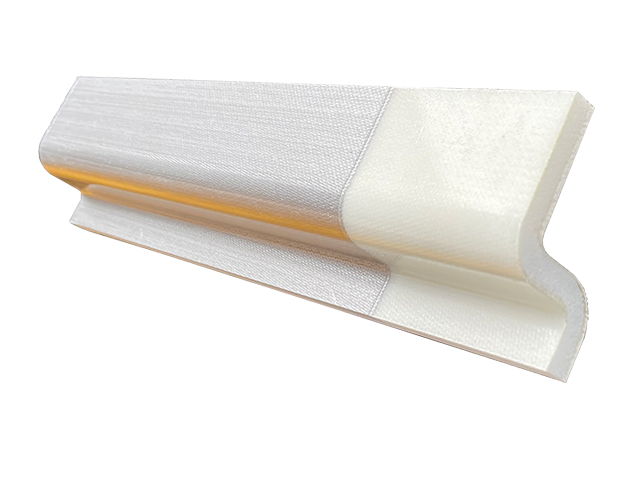

Together with our partners, we have developed a sustainable sidewall panel that takes advantage of the performance of the structural foam core Divinycell F and combines it with thermoplastic skins. Using only materials already tested and qualified by aerospace OEMs, the panel is fully compliant with all industry requirements yet 100% recyclable. It also provides all the advantages of a one-step manufacturing process. Come and see it for yourself in our stand!

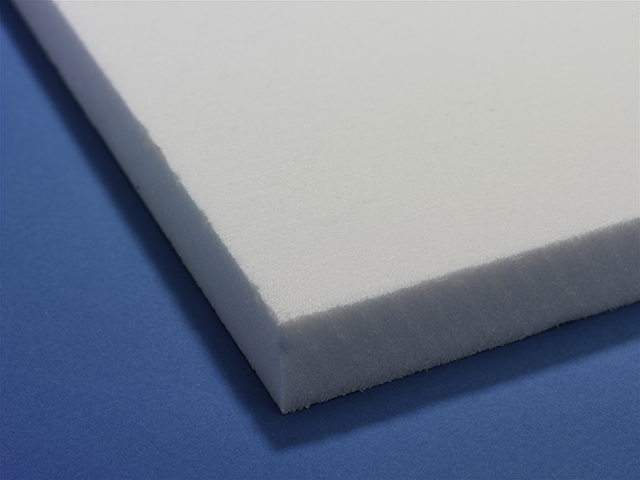

This foam is a recyclable, prepreg-compatible sandwich core offering excellent fire, smoke, and toxicity (FST) properties and good mechanical and processing characteristics. It meets the US and European regulatory requirements for commercial aircraft interiors. Other key features include processing up to 220°C, exceptional fatigue life, good chemical resistance, excellent heat ageing at 180°C, and a zero-waste production process. Divinycell F is compatible with the most common aerospace composite manufacturing processes.

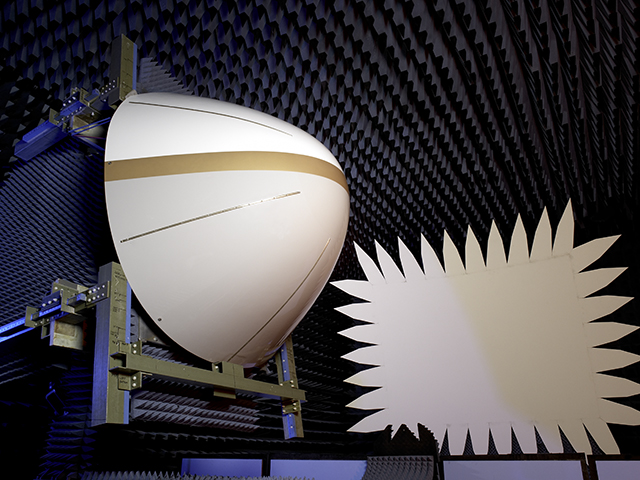

Apart from aircraft interiors, our core materials can be found in weather radomes and satcom/Wi-Fi radomes since they offer excellent dielectric properties, easy thermoforming, and impact resistance. The core materials give the final product excellent panel transparency and a longer life cycle, saving maintenance and repair costs while decreasing carbon footprint.

Divinycell U combines a high strength-to-weight ratio with low moisture absorption. It also possesses excellent Fire, Smoke and Toxicity (FST) properties. The PEI foam core is compatible with most high-temperature aerospace and defence composite manufacturing processes.

The aerospace industry has been driven by life cycle cost and weight reduction for decades. Still, we see increasing demands for sustainable applications and production methods to decrease the global footprint.

Air traffic habits are changing fundamentally, and new applications must serve new trends.

Diab has decades of experience serving the aerospace industry. Our unique insights into products and processes and innovative approach have enabled us to create a wide and valuable offering. Through our technical department, we combine high-performance materials with top-level engineering services and application training.

We are on an ambitious journey to fully embrace a circular economy, creating a whole new level of sustainability. But we also want to be the best partner for companies that want to improve their circularity and lower their carbon footprint.

At AIX, you can learn more about the circular business model and how your company can benefit from our knowledge and sustainable renewable materials.

The global community is facing a daunting challenge in the form of climate change, and urgent action is required to mitigate its impact.

Read moreA circular business model reduces the use of material and energy resources and redesigns materials

Read moreDownload our guide how to find the most sustainable core for your application

Download