Divinycell H

Excellent mechanical properties to low weight.

Read moreHey there!

Do you have any questions or are you ready to dig deeper into your projects with one of our experts? We are here for you.

Don't have an account?

Sign upSign in to MyDiab

Or log in with

Optimized infusion and greater design freedom enable the creation of stronger, lighter blades with a lower total cost of ownership.

Designing wind turbine blades is a complex balancing act, where weight, strength, processability, and sustainability must all align. At the heart of this balance lies the core material, and Diab provides the building blocks to make it work.

Our PET and PVC cores are key components in composite blades for both onshore and offshore wind applications. Blade designers choose core type and density based on overall performance targets and structural requirements. Many bills of materials (BOMs) today combine two or even three core types in a single blade, utilizing high-density grades in stress-critical areas, such as spars and webs, and lower densities in the shell to minimize weight.

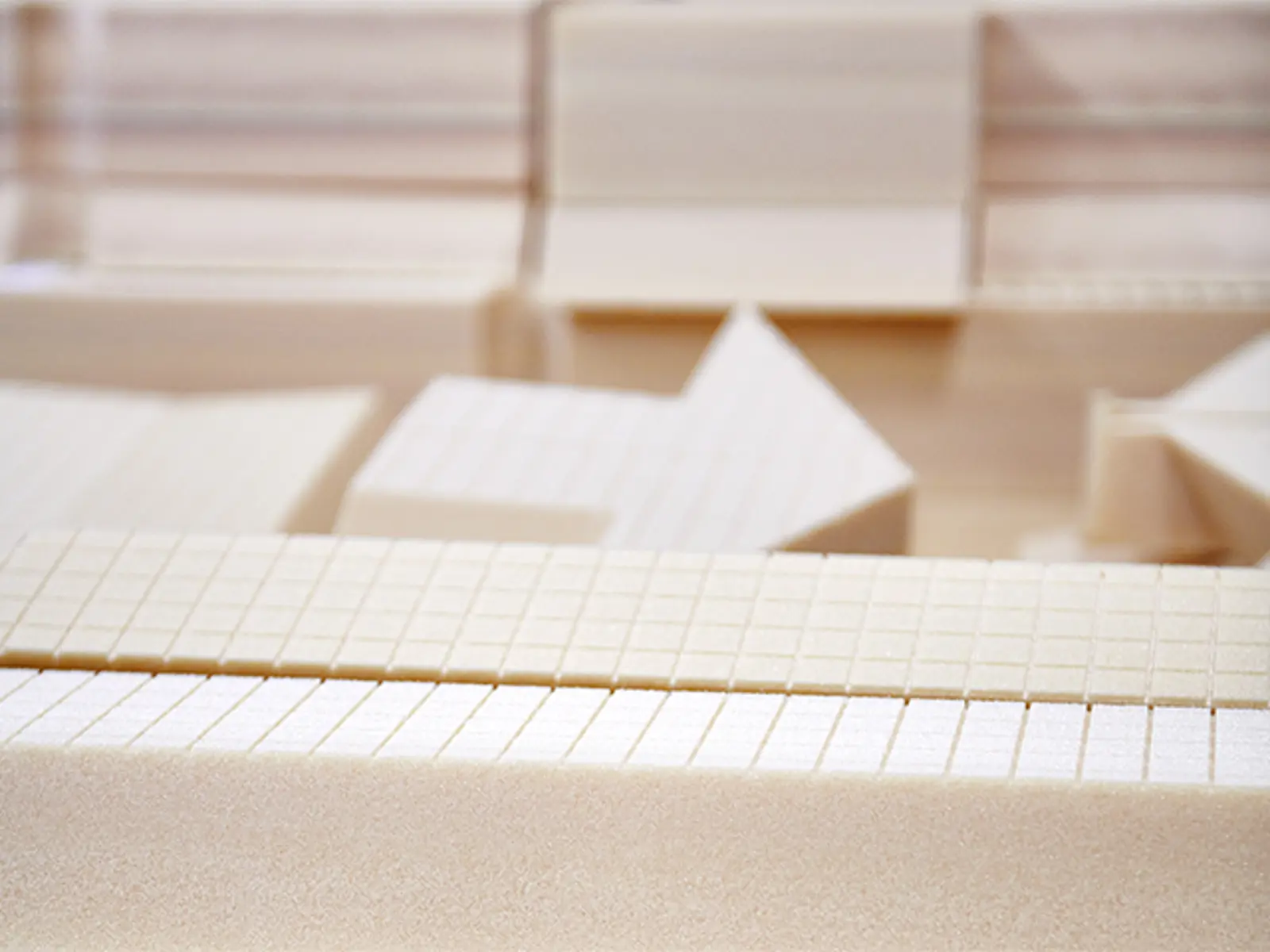

Beyond performance, Diab’s cores also play a vital role in manufacturing. Thanks to a wide range of finishing options, such as perforations, grooves, cuts, and full kitting, our materials serve as efficient processing aids during resin infusion. This enables faster production, better flow control, and even reductions in resin usage. The result is a blade that is not only structurally optimized but also cost-efficient to manufacture.

With a deep understanding of the wind industry’s needs, Diab offers a complete portfolio of core materials, finishing solutions, and technical services. As a reliable, independent partner with a secure global supply chain and adherence to the APQP4Wind Manual, we support blade manufacturers at every step, from concept to tooling to serial production, helping them meet the demand for faster, more innovative, and more sustainable wind energy solutions.

Recyclable high performance PET core material based on post-industry recycled PET content with very low resin uptake.

Read moreReduce cost, decrease weight and improve quality – with the optimal finishing you can get a competitive edge.

Find out moreImprove efficiency, lower your cost, increase quality – boost performance with pre-cut parts.

Find out moreFind and download certificates, datasheets and other documents here.

DownloadFind the tools and services you need to draw all the benefits from our materials.

See our tools

To ensure that we give you the best experience on our website. Find out more about the cookies we use in our cookie policy.

Required

These cookies are required in order for the website to function normally.

Statistics

These cookies are used to collect statistical information.

Marketing

These cookies are used for marketing-related purposes.