Divinycell H

Excellent mechanical properties to low weight.

Read moreHey there!

Do you have any questions or are you ready to dig deeper into your projects with one of our experts? We are here for you.

Don't have an account?

Sign upSign in to MyDiab

Or log in with

Next-gen nacelles and spinners built with Diab’s high-performance core materials.

In modern wind turbines, nacelles and spinners are more than covers; they’re essential to protecting critical systems and optimizing aerodynamics. To meet demanding cost and performance targets, many manufacturers rely on sandwich composite technology. At the core of these solutions, literally and figuratively, is Diab.

For non-structural nacelle applications, where the goal is to create a weatherproof, aerodynamic housing at the lowest possible cost, Diab offers lightweight PET and PVC core materials in low densities. For more advanced structural nacelle designs, often sharing properties with blade construction, we provide higher-grade solutions that can meet tougher strength and stiffness demands.

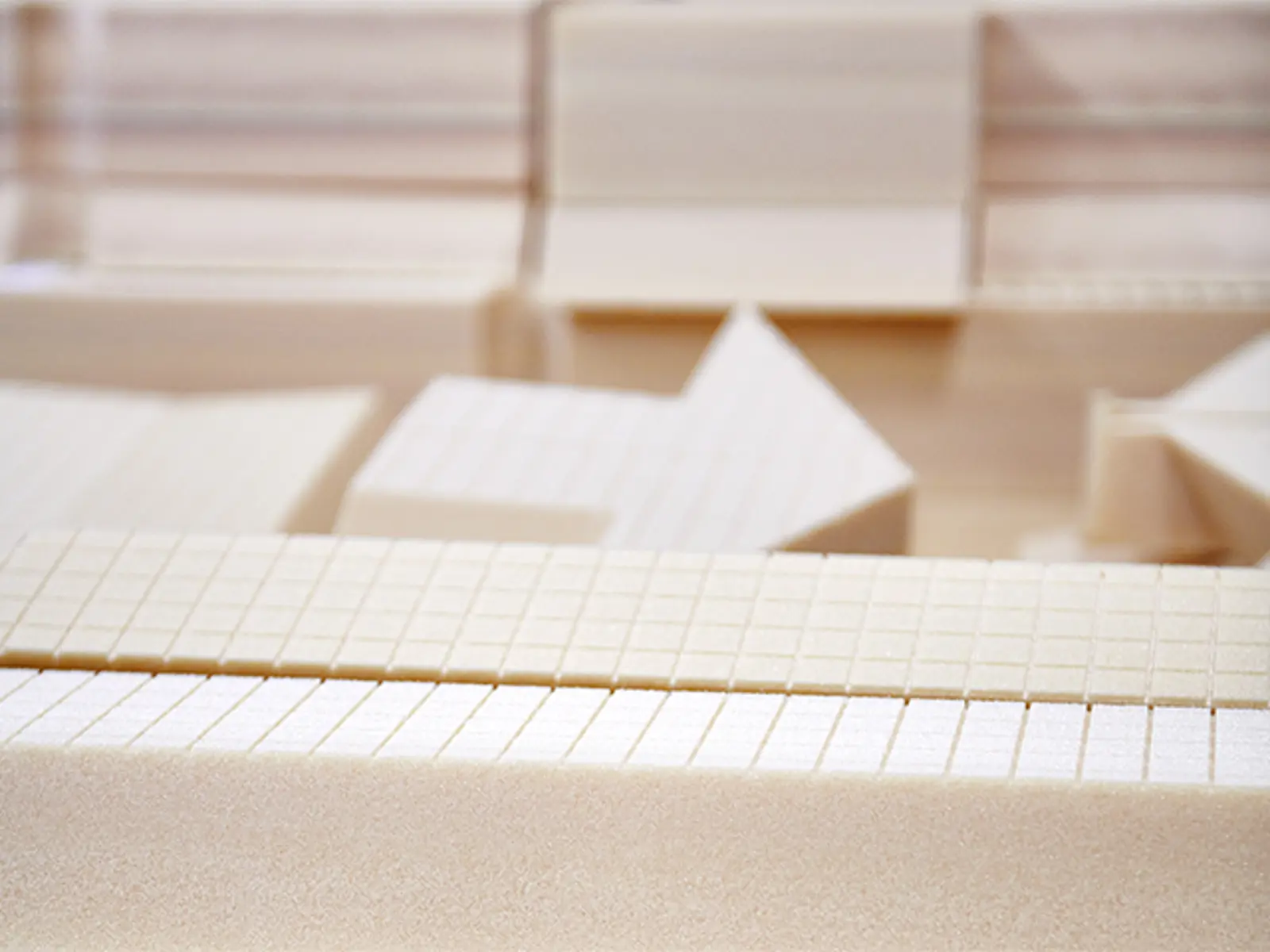

What sets Diab apart is our ability to enhance both design and production. Our finished and kitted cores, perforated, grooved, and precision-cut, help streamline the resin infusion process. This results in faster cycle times, reduced resin consumption, and more consistent product quality. These processing benefits significantly lower the total cost of production while maintaining excellent structural performance and design freedom.

With a comprehensive offering of core materials, finishing, and complete kitting services, Diab supports OEMs and nacelle manufacturers in building lighter, smarter, and more cost-effective nacelle and spinner systems, ensuring their turbines perform optimally from base to blade tip.

Recyclable high performance PET core material based on post-industry recycled PET content with very low resin uptake.

Read moreReduce cost, decrease weight and improve quality – with the optimal finishing you can get a competitive edge.

Find out moreImprove efficiency, lower your cost, increase quality – boost performance with pre-cut parts.

Find out moreFind and download certificates, datasheets and other documents here.

DownloadFind the tools and services you need to draw all the benefits from our materials.

See our tools

To ensure that we give you the best experience on our website. Find out more about the cookies we use in our cookie policy.

Required

These cookies are required in order for the website to function normally.

Statistics

These cookies are used to collect statistical information.

Marketing

These cookies are used for marketing-related purposes.