Flow

To distribute resin and to evacuate air.

Read moreHey there!

Do you have any questions or are you ready to dig deeper into your projects with one of our experts? We are here for you.

Don't have an account?

Sign upSign in to MyDiab

Or log in with

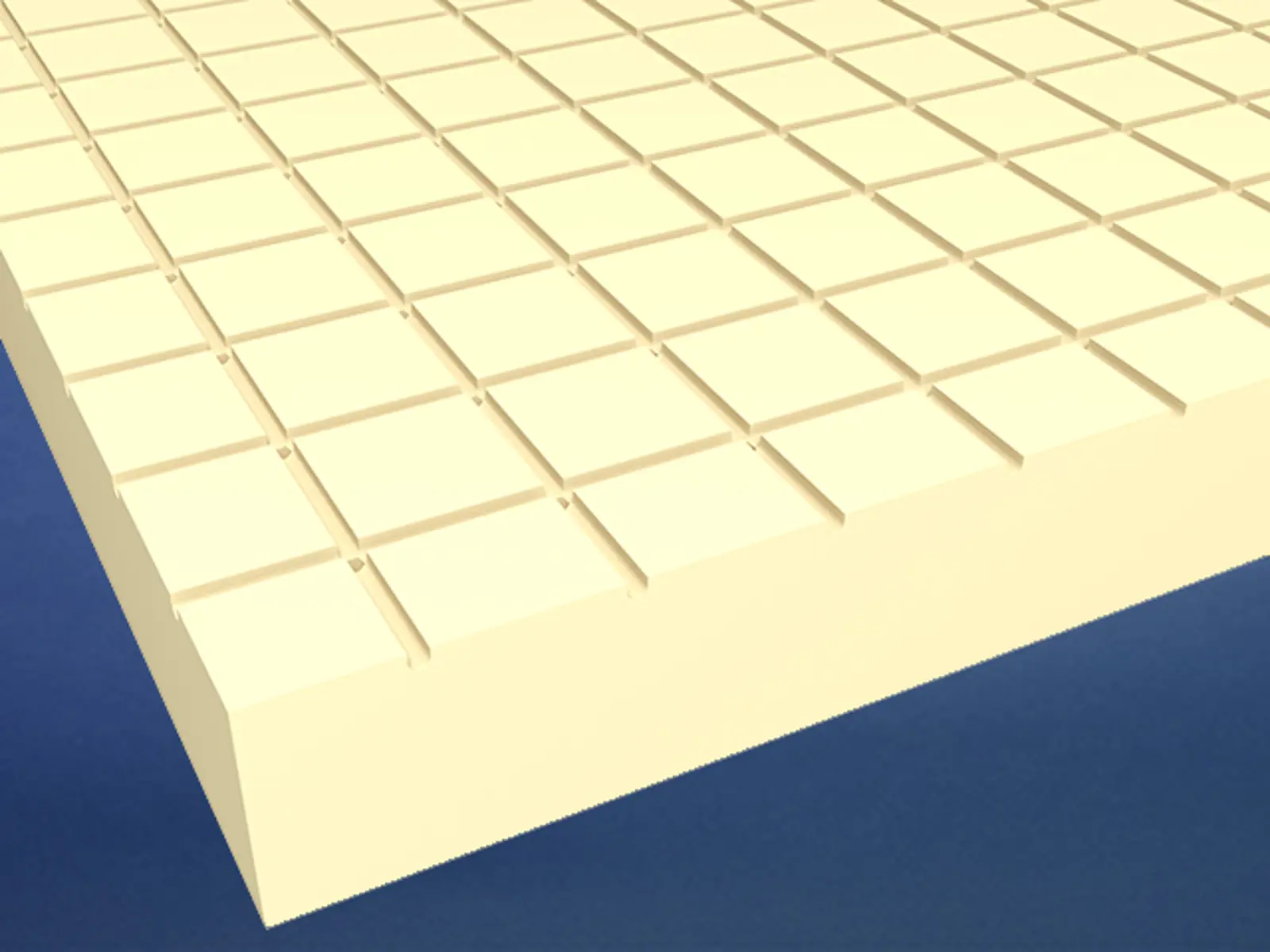

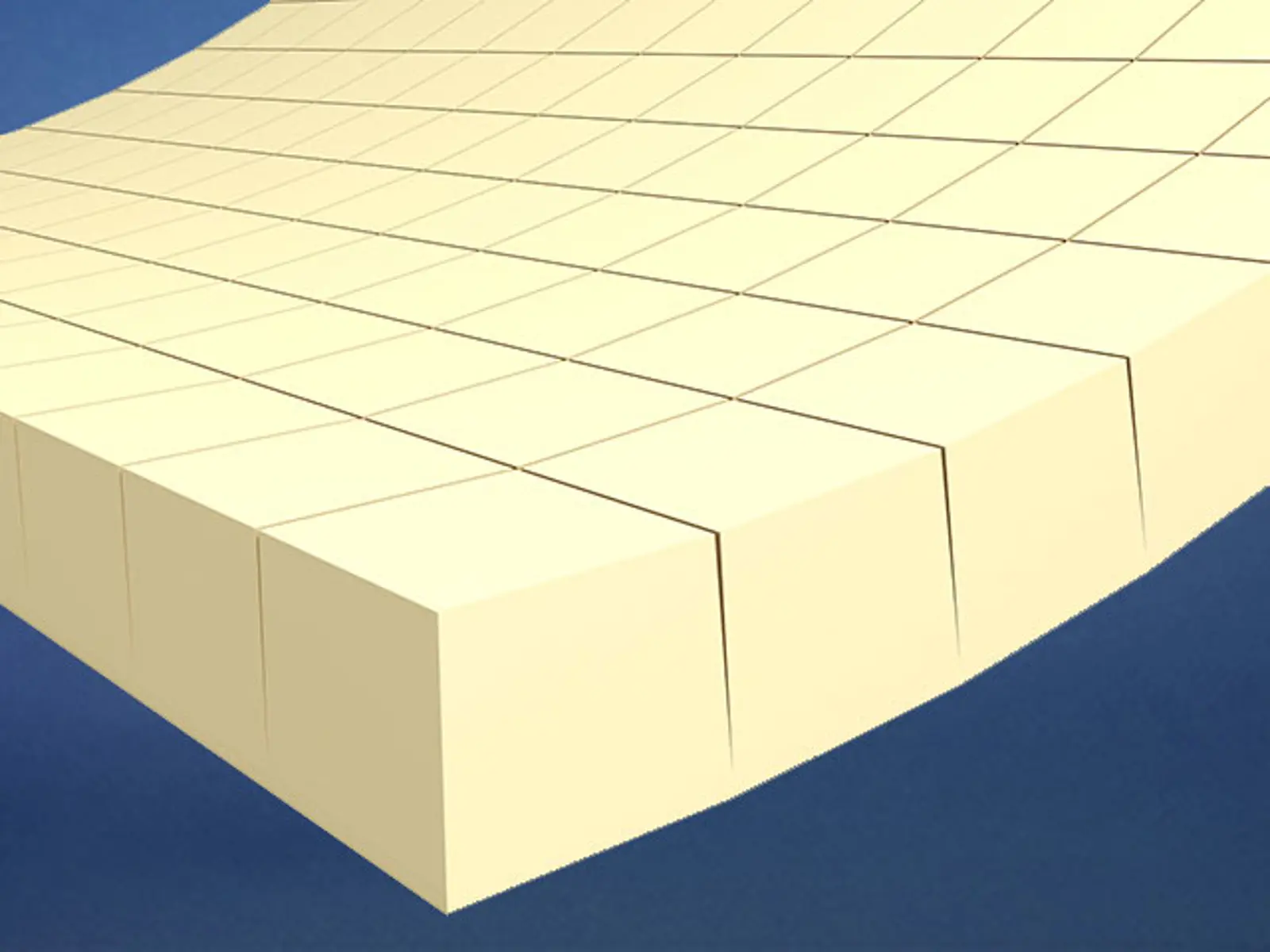

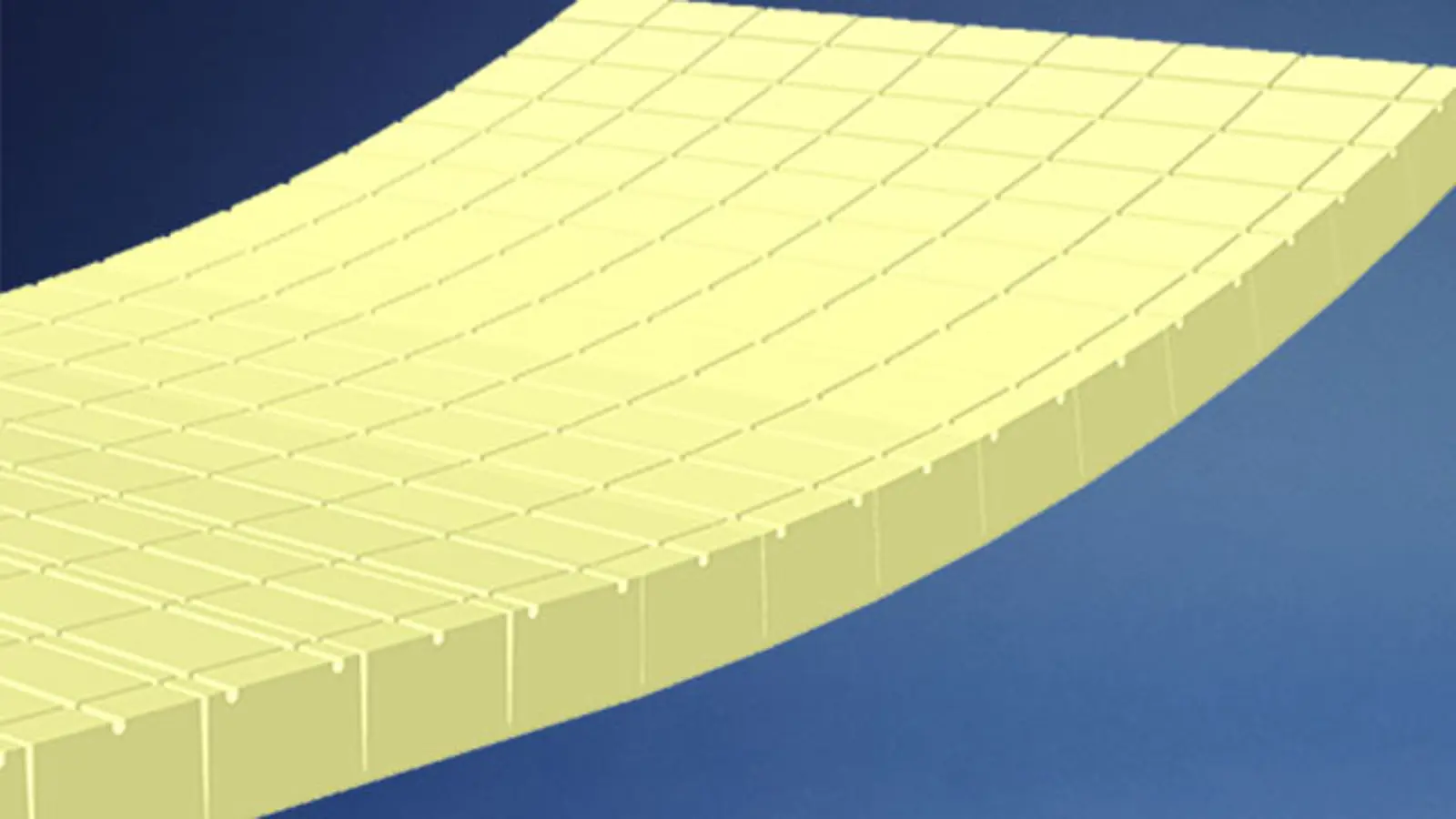

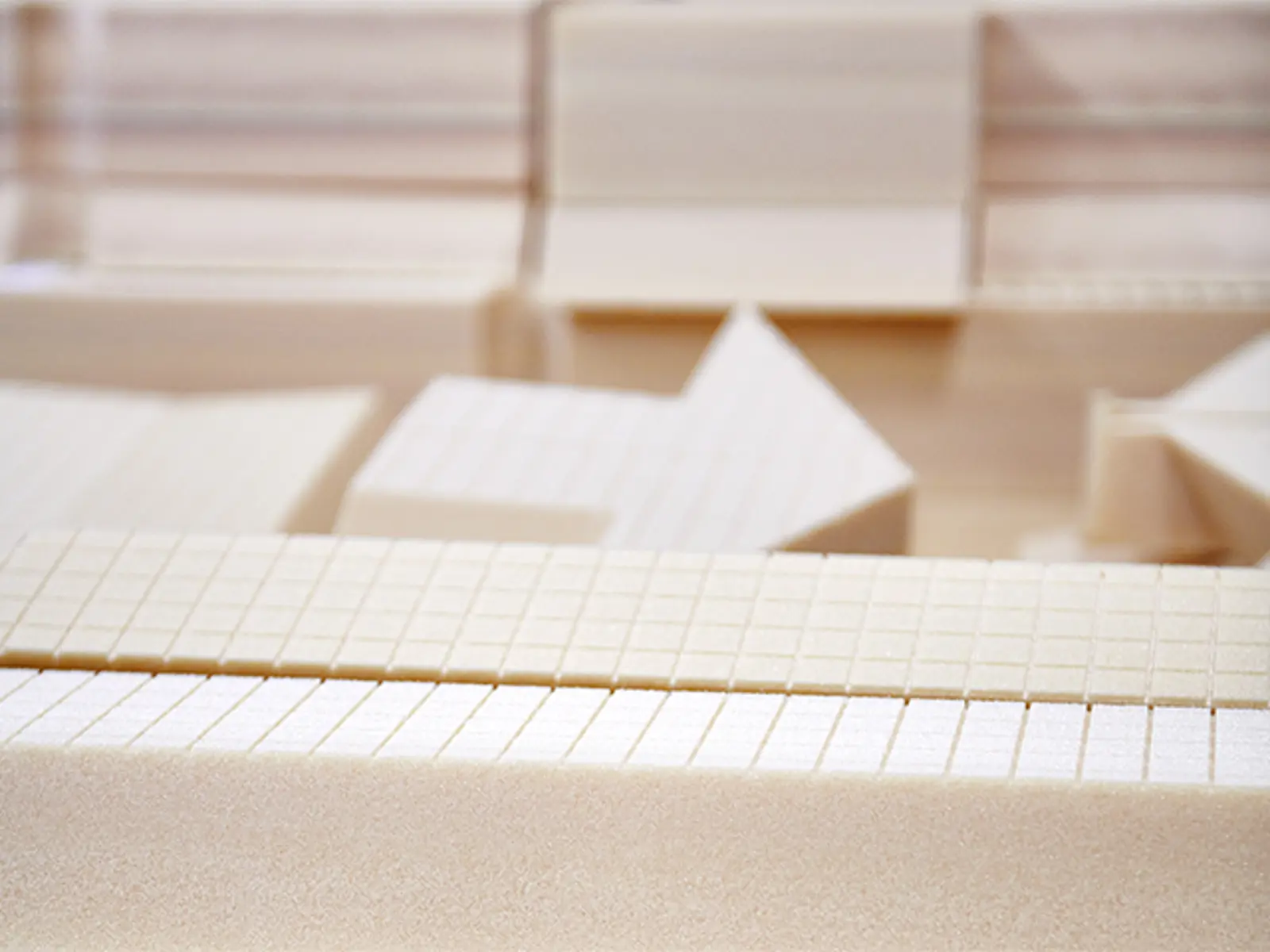

Finishing refers to the machining of structural core materials. You can choose from a wide range of cuts, grooves and perforations in different patterns, which, when combined and customized, will optimize the final solution.

Why finishing?

Depending on the geometry, manufacturing process or specific component requirements, the selected finishing will have an important part to play in a successful result.

Why finishing from Diab?

Diab is a world-leading supplier of sandwich core materials, with long experience in developing finishing solutions. Diab has pioneered many areas, including infusion and vacuum bagging. With in-depth technical knowledge in most manufacturing methods for composites, we understand what criteria are essential for the finishing to fit the purpose. We select the most appropriate one from our wide selection of finishes for form and/or flow, based on the requirements.

Selecting the optimal finishing

The complexity of the component and the curvature of the mould influence which core finishing fits best into the mould shape, with a minimum of spring-back and reduced resin consumption. Together with the geometry and expected performance of the product, it is crucial to analyze the finishing used for each manufacturing method used. The choice of finishing will have a strong impact not only on the manufacturing of the product but also on its final performance.

Diab offers a wide range of cuts, grooves and perforations in different patterns, serving several purposes: Form, Flow, and Flow & Form.

Diab also offers an innovative core-slitting technology to cut the material into extremely thin sheets with very tight tolerances. The benefits include a very smooth surface finish, 3D formability and decreased resin uptake – up to 30% depending on the core type and grade. Contact Diab to find out more about this option, which is suitable for extremely lightweight applications.

Contact Diab to find out more about this option, which is suitable for extremely lightweight applications.

Improve efficiency, lower your cost, increase quality – boost performance with pre-cut parts.

Find out moreFind and download certificates, datasheets and other documents here.

DownloadFind the tools and services you need to draw all the benefits from our materials.

See our toolsImprove efficiency, lower your cost, increase quality – boost performance with pre-cut parts.

Find out more

To ensure that we give you the best experience on our website. Find out more about the cookies we use in our cookie policy.

Required

These cookies are required in order for the website to function normally.

Statistics

These cookies are used to collect statistical information.

Marketing

These cookies are used for marketing-related purposes.