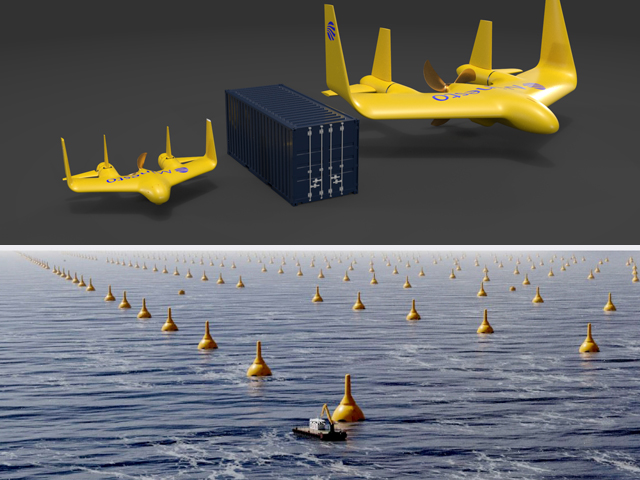

Explore new sustainable solutions and circular core materials at JEC World 2023

It’s time to get circular, and Diab is taking the lead in becoming the core partner for companies searching for sustainable products and solutions. At JEC World in Paris, April 25-27, 2023, we are excited to present circular thinking around core materials and technical solutions to make our customers’ applications more sustainable. Here are some of the product highlights and latest innovations we will present.