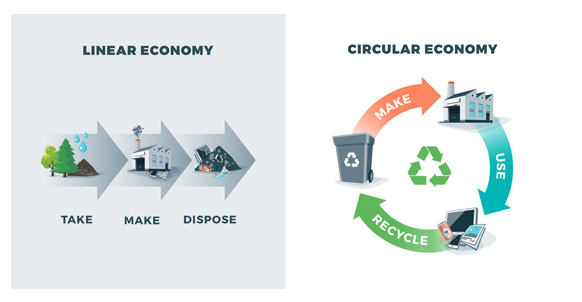

The circular economy is all about reducing and recycling

The circular economy changes the linear business model in which raw materials are mined, made into products, and discarded when their life cycle ends. In a circular economy, companies recycle by-products as a resource to manufacture new materials and products, creating big gains both for companies and the environment. It also reduces the use of resources, both material and energy, and redesigns materials, products, and services to be less resource intensive to produce.

The circular business model turns this thinking into a sustainable and profitable process because there are economic gains to be made by greater resource efficiency. In a linear business model, resources are used once and discarded, leading to higher costs and overexploitation of Earth’s resources. In a circular business model, resources are used more efficiently, reducing the need for virgin resources and lowering costs.

The benefits of reducing the use of resources

Research from the Institute for Manufacturing (IfM), a part of the University of Cambridge’s Department of Engineering, calculates that if every factory in a sector moved towards optimum sustainable performance, there could be 24% profit gained, 30% more jobs generated, and 9% less greenhouse gas shared across that sector.

According to IfM, shifting from disposal methods to reduction and recycling processes can bring many benefits, including increased profit by saving money through more efficient use of raw materials, improved reputation, and greater environmental responsibility.

The supply chains hold the key

The global consumer sector is expected to grow 5% annually for the next two decades. Research by McKinsey estimate that more than half of the enterprise value of the top 50 consumer companies depends on their projected growth. But this growth is vulnerable to issues such as drought, government limits on greenhouse-gas emissions, and reputational damage from insufficient attention to pollution and safety.

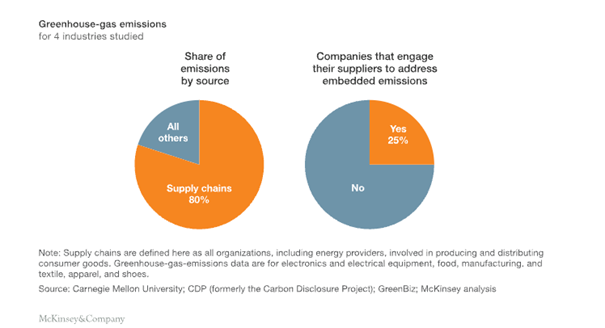

That’s why many companies are working to manage their sustainability performance. And when doing this, they often start with their operations. However, the largest improvement opportunities can probably be found in supply chains (Scope 3). These typically account for 80 per cent of a consumer business’s greenhouse-gas emissions and more than 90 per cent of its impact on air, land, water, and biodiversity. Therefore, it is crucial to solving sustainability challenges along the entire supply chain.

However, fewer than 20 per cent of the 1,700 respondents to a survey by the Sustainability Consortium are doing this. Best-practice companies assist suppliers with managing sustainability impact, offering incentives for improved performance, sharing technologies that can help optimise the use of resources such as water and soil, and closely monitoring performance to be able to intervene quickly when problems arise.

Diab’s circular business model

This is why Diab is implementing a circular business model. Instead of a linear model where materials travel through the system in one direction, it will be circular both in sales and sourcing. For example, if we can reuse post-industrial plastic waste from our and our customers' processes, we can reduce our and our customer’s carbon footprint and the cost of handling by-products.

But our effort to reduce our carbon footprint goes beyond managing Diab’s sustainability performance. We also work with our supply chain (Scope 3) because supporting our suppliers in lowering their emissions benefits our products, which benefits our customers' applications. It’s a chain effect that works in both directions.

Diab’s circular business model

1. We make products with recycled raw materials, which lowers our carbon footprint in line with the Science Based Targets and, thereby, our customers’ carbon footprint. We have high sustainability goals, use renewable energy in our plants and are researching bio-based raw material alternatives.

2. The customer can use a recycled product in their application, lowering their carbon footprint. The low weight also contributes to a lower footprint during the application’s life cycle. Our materials also have an extreme life span, making them beneficial in the life cycle assessment.

3. Our products can easily be recycled or reused because Diab is transparent and provides clear information about the included materials. That makes it possible to reuse foam at end of life from one application to produce new foam or use it in other products.

Sources:

“Reducing waste in manufacturing” Institute for Manufacturing (IfM), Department of Engineering, University of Cambridge

https://engage.ifm.eng.cam.ac.uk/project/reduce-waste-in-manufacturing/

“Mapping the benefits of a circular economy”, McKinsey & Co

To find out more about how Diab can help you reduce your carbon footprint and use recycled core materials to make a more sustainable application, contact us!